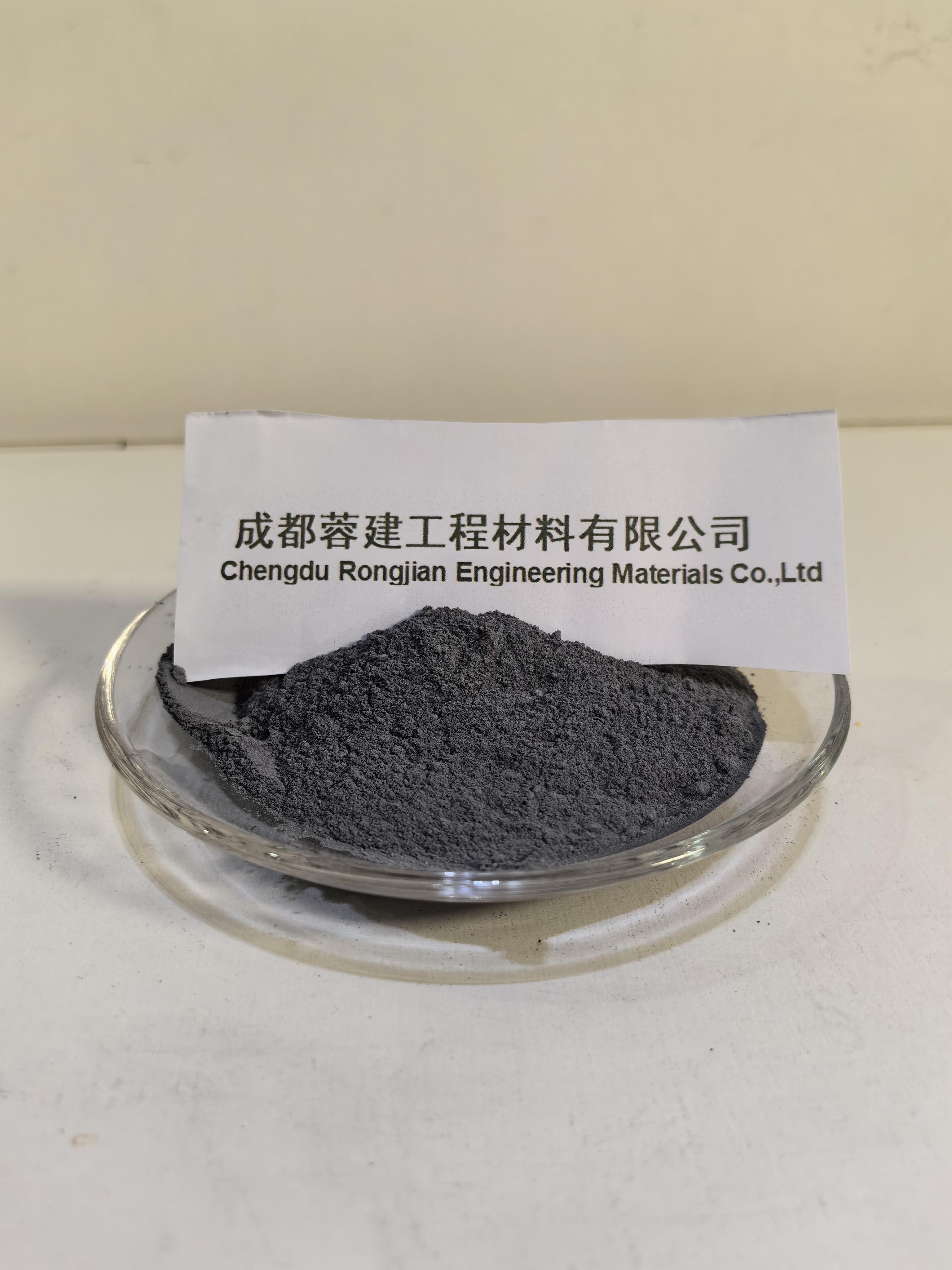

Densified Silica Fume is to improve the density of micro-silica fume in order to reduce the transportation cost and improve the use performance. Before Densified, its density is about 150 to 200 kg/m³, after densified, it can reach 700 kg/m³, which greatly reduces the volume and improves the particle size at the same time. The densified process used nowadays is to use the airflow formed by compressed air to prompt the micro-silica fume in the container to collide with each other and rely on its own aggregation and adsorption to exclude the surface gas, thus forming multiple small particles with increased capacity to achieve the purpose of densified. 94% Undensified Microsilica, 94% Unencrypted Silica Fume, 94% Non-encrypted Silica Fume Chengdu Rongjian Engineering Materials Co.Ltd , https://www.rjsilicafume.com

Roots vacuum pump works (with photos)

Roots vacuum pump (Roots pump) is a rotary varactor vacuum pump. It was evolved from a Roots blower. Roots vacuum pump according to the different scope of work, is divided into straight row of atmospheric vacuum Roots pump; vacuum Roots pump (also known as mechanical booster pump) and high vacuum multistage Roots pump. In general, Roots vacuum pump works Features: In a wide range of pressure has a larger pumping speed; Quick start, can work immediately; The exhaust gas is not sensitive to dust and water vapor; Rotor does not have to be lubricated , No oil in the pump cavity; small vibration, good rotor balancing condition, no exhaust valve; small driving power and small mechanical friction loss; compact structure and small area; low operation and maintenance cost. Therefore, Roots vacuum pump in the metallurgical, petrochemical, paper, food, electronics industry sector has been widely used. Roots vacuum pump works: Roots pump structure as shown. In the pump chamber, two "8" -shaped rotors are mounted perpendicular to each other on a pair of parallel shafts and are rotated synchronously by a pair of gears having a transmission ratio of 1 in opposite directions. Between the rotors, between the rotor and the pump housing to maintain a certain gap, you can achieve high-speed operation. Because Roots vacuum pump is a type of vacuum pump without internal compression, the compression ratio is usually very low, so the high and medium vacuum pumps need foreline pump. Roots pump ultimate vacuum in addition to depend on the pump structure and manufacturing accuracy, but also depends on the foreline pump ultimate vacuum. In order to increase the pump ultimate vacuum, Roots pumps can be used in series. Roots vacuum pumps work like Roots blowers. Due to the constant rotation of the rotor, the drawn gas is sucked into the space v0 between the rotor and the pump housing through the air inlet and then discharged through the air outlet. Since inhaled v0 space is completely closed state, so the gas in the pump chamber is not compressed and expanded. However, when the top of the rotor turns over the edge of the exhaust port, when the v0 space communicates with the exhaust side, since the pressure of the exhaust side gas is higher, a part of the gas bounces back into the space v0 to make the gas pressure suddenly increase. When the rotor continues to rotate, the gas is discharged outside the pump. The picture shows the working principle of Roots vacuum pump, the rotor from 0 ° to 180 ° of the extraction process. In the 0 ° position (a), the lower rotor encloses v0 volume of gas from the pump inlet. When turned to 45 ° position (Figure b), the chamber communicates with the exhaust port. As the exhaust side of the higher pressure, causing part of the gas back to punch over. When turned to the 90 ° position (c), the gas enclosed by the lower rotor is vented to the pump together with the backflushing gas. At this time, the upper rotor is also filled with v0 volume of gas from the pump inlet. When the rotor continues to rotate to 135 ° (d in the figure), the gas enclosed in the upper rotor communicates with the exhaust port, and the above process is repeated. The 180 ° (Figure e) position is the same as the 0 ° position. A total of four v0 volume of gas is discharged during one revolution of the rotor shaft.

94% Undensified Silica Fume is a micro-silica fume with 94% SiO2 content, and the Bulk density is 250-400kg/m³.